The saw tooth pattern can be seen in the dipole and SSS measurements, where the cold bore tube axis is measured twice - from two different tube extremities. The effect is more important in the vertical plane.

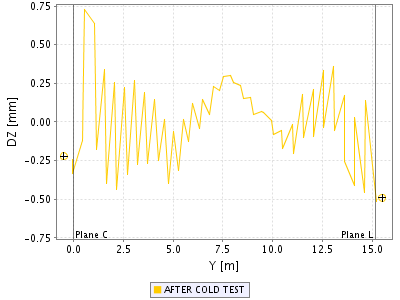

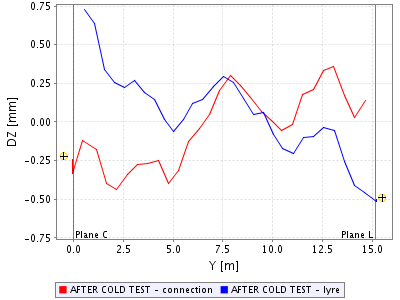

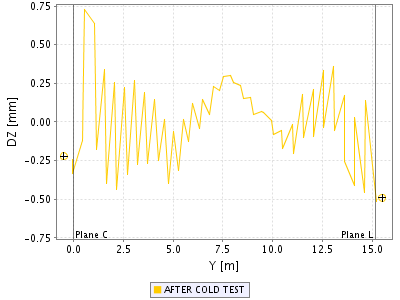

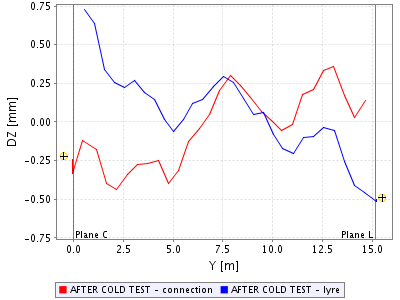

Here is the example: dipole 2248, step WP08-FID, vertical plane. Left plot shows the graph with merged points, right plot shows two curves separately:

|

|

|---|

The analysis of the saw tooth effect was presented on MAS-MA seminar 9 February 2006 saw_tooth.ppt.

The analysis of possible laser beam deflection due to the temperature gradient in the tube is given

here.

The status of the outliers detection study is given

here (last updated 21-MAR-2006).

The results of the analysis of all valid measurements with both sides

completely measured are stored in the database tables MAS_PDA.X_AXIS_STAT_DX and

MAS_PDA.X_AXIS_STAT_DZ

and can be updated on request (the script for the update).

Last update was performed on December, 12th 2006 for ITP20-GEO and last step at WP08 only.

The information given in the tables is:

| MAGNET_NU | magnet number |

| STEP | step |

| MEAS_DATE | measurement date (from the table CRYOGEO_MEAS_ENV) |

| MEAS_RMS | bundle adjustment RMS (from the table CRYOGEO_MEAS_ENV) |

| OPERATOR | operator (from the table CRYOGEO_MEAS_ENV) |

| LASER_TRACKER | laser tracker number (from the table CRYOGEO_MEAS_ENV) |

| ROOM_TEMPERATURE | room temperature (from the table CRYOGEO_MEAS_ENV) |

| MAGNET_TEMPERATURE | magnet temperature (from the table CRYOGEO_MEAS_ENV) |

| APERTURE | aperture (1 or 2) |

| CORR_COEFF | correlation coefficient between 2 curves |

| SLOPE | linear regression slope of the difference between two curves |

| INTERC | linear regression Y-intercept (shift) of the difference between two curves |

| R2 | difference linear regression R2 value |

| RMS | difference linear regression RMS |

| DIFF | average difference between two curves [mm] (integral divided by the length) |

| DIFF_ABS | average absolute difference [mm] (integral divided by the length) |

| AVG_ABS_DIFF | average of the absolute difference [mm] (simple average over all points) |

| STD_ABS_DIFF | standard deviation of the absolute difference [mm] |

| MAX_ABS_DIFF | max absolute difference [mm] |

| MIN_ABS_DIFF | min absolute difference [mm] |

Based on this data we can choose the measurement which have big saw tooth

(AVG_ABS_DIFF + 3 STD_ABS_DIFF > 0.47)

or have "parralel" curves far one from another

(DIFF_ABS - ABS(DIFF) < DIFF_ABS/10000 and DIFF_ABS > 0.2) etc.

A saw tooth correction procedure was proposed by E.Wildner

(

E.Wildner, AT-MAS Technical Note 2006-01).

Test of this procedure on a simple

linear case (notebook).

Detailed study of the two industry measurements of the dipole 2273, fit in 2D, last updated on 20.04.2006 (with the minimization of the saw tooth between curves).

The saw tooth procedure was presented on the WGA meeting in May 2006:

Notebook with the correction procedure (version 12 December 2006),

retrieves the data from the database

for the magnets specified in a custom query and stores the resuls in the table MMSMA.AUX_CRYOGEO_SAW_TOOTH.

The data from thsi table are then used in the PDA Dipole Geometry Viewer (saw tooth analysis page).